Product Description

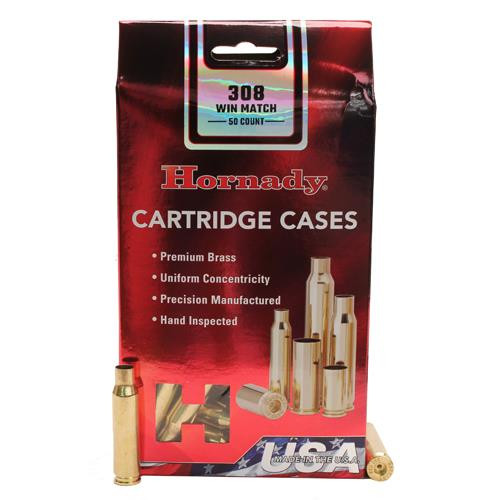

Hornady 308 Win Unprimed Brass Cases 50 Count

#8661

Overview

Hornady brass is the foundation for what could be the most memorable shot of your lifetime. Extra time and care is taken in the creation of Hornady cases, producing smaller lots that meet strict quality standards. Their cases offer reloaders excellent uniformity in wall thickness, weight and internal capacity.

Hornady measures for consistently tight wall concentricity and even run their cases through a pressure calibration test to ensure uniform case expansion during firing. Hornady cases allow proper seating of the bullet, not only in the case, but in the chamber as well. High quality brass contributes to consistent charges and pressures.

Brass Preparation

With bulk rifle brass you may sometimes notice a few case mouths are “out of round” or slightly dented below the shoulder. These imperfections occur in the final tumbling wash operation after the case mouth has been annealed. Brass manufacturers are aware of the case cosmetics and have worked to mitigate it, but due to equipment design, denting may still occur. Minor dents are normally removed in the first firing and will not affect case life or performance. On non-plated brass, you may also notice all the anneal stain might not be polished off, which may give the case neck a pinkish color. With some smaller caliber cases you may notice the case mouths to be slightly belled.

With all new rifle brass, you should first straighten out the case and case mouth, then chamfer and debur the case mouth inside and out. To straighten the case mouth, run the case part way into the sizer die and let the expander ball straighten the brass. To prevent the case neck from stretching, be sure to lubricate the case neck inside the case mouth.